Enhanced plasma discharge (Epd)

A quantum leap for gas chromatography sensing

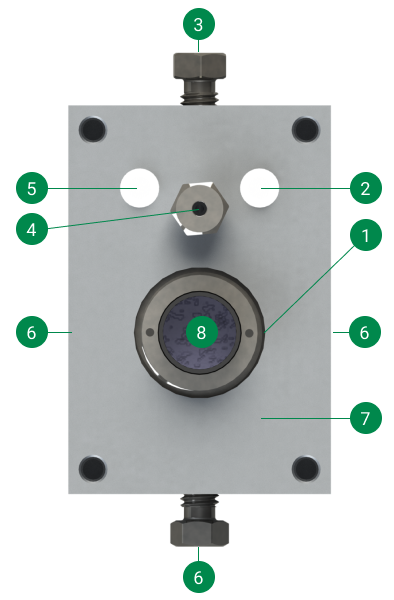

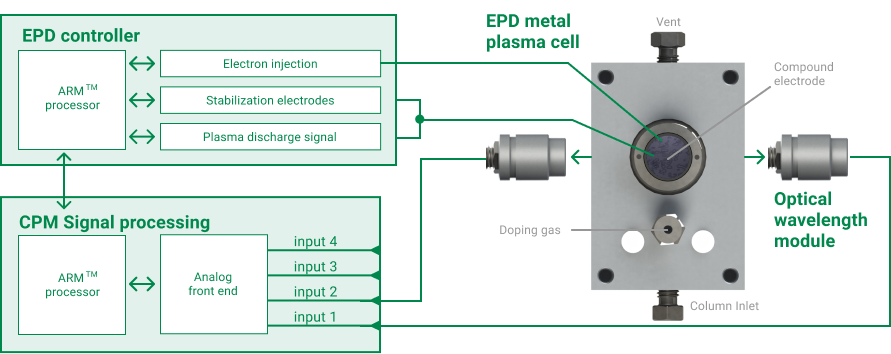

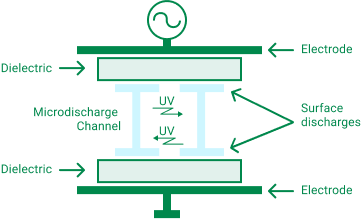

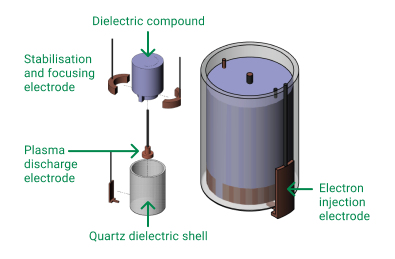

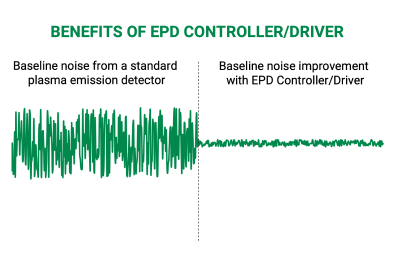

The Epd (enhanced plasma discharge) is our proprietary gas detector technology based on a stabilized dielectric barrier discharge (DBD) plasma. The breakthrough resides in the focusing and stabilizing compound electrodes (patent pending) which generate a more stable plasma discharge across a broad range of operating conditions. It uses the highly energetic plasma behaviors to perform measurements. Its versatility and sensitivity make it a technology of choice to measure molecules with high ionization potential, such as the permanent gases, as well as molecules with lower ionization potentials, such as VOCs, hydrocarbons and sulfurs, from ppt to % range.

沪公网安备31011302007575号

沪公网安备31011302007575号